| Feb 24, 2023 |

|

(Nanowerk Information) Photo voltaic cells constructed from perovskite, a cloth that is ready to harvest daylight and convert it to electrical energy, maintain nice potential as a substitute for silicon photo voltaic cells.

|

|

Regardless of superior efficiency, effectivity and being cheaper to fabricate, perovskite photo voltaic cells haven’t been commercially manufactured for the buyer market.

|

|

Perovskites decompose after they react with moisture and oxygen or when they’re uncovered to mild, warmth, or used for an prolonged time, leading to considerations that the small quantity of lead, a poisonous heavy steel, current in perovskite photo voltaic cells might pollute the surroundings when the photo voltaic cell is broken or discarded.

|

|

The lead comes from each the perovskite materials and a compound used to make a element of the perovskite photo voltaic cell, referred to as the capping layer.

|

|

Now, analysis by scientists from Nanyang Technological College, Singapore (NTU Singapore) and the Institute of Supplies Analysis and Engineering (IMRE) on the Company for Science, Know-how and Analysis (A*STAR) in Singapore has supplied the potential for capping supplies primarily based on non-toxic metals getting used within the manufacture of perovskite photo voltaic cells.

|

|

Their research, printed in Nature Power (“Increasing the low-dimensional interface engineering toolbox for environment friendly perovskite photo voltaic cells”) and led by Professor Sum Tze Chien, Director of the Institute of Superior Research at NTU and Affiliate Dean (Analysis) of NTU’s School of Science, and Professor Lam Yeng Ming, Chair of NTU’s Faculty of Supplies Science and Engineering, might take perovskite photo voltaic cells one step nearer to the market.

|

Stabilising perovskite photo voltaic cells with out lead

|

|

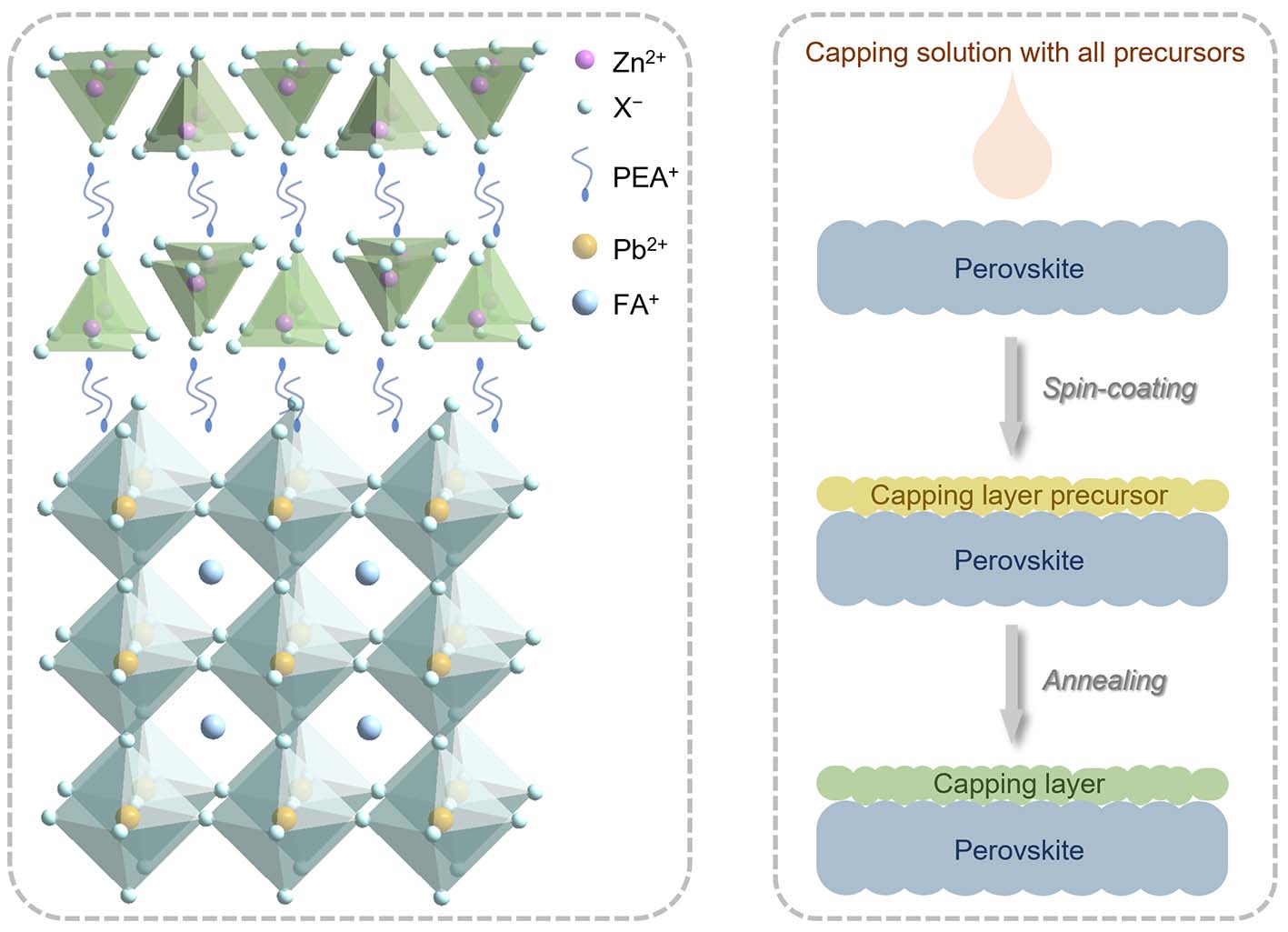

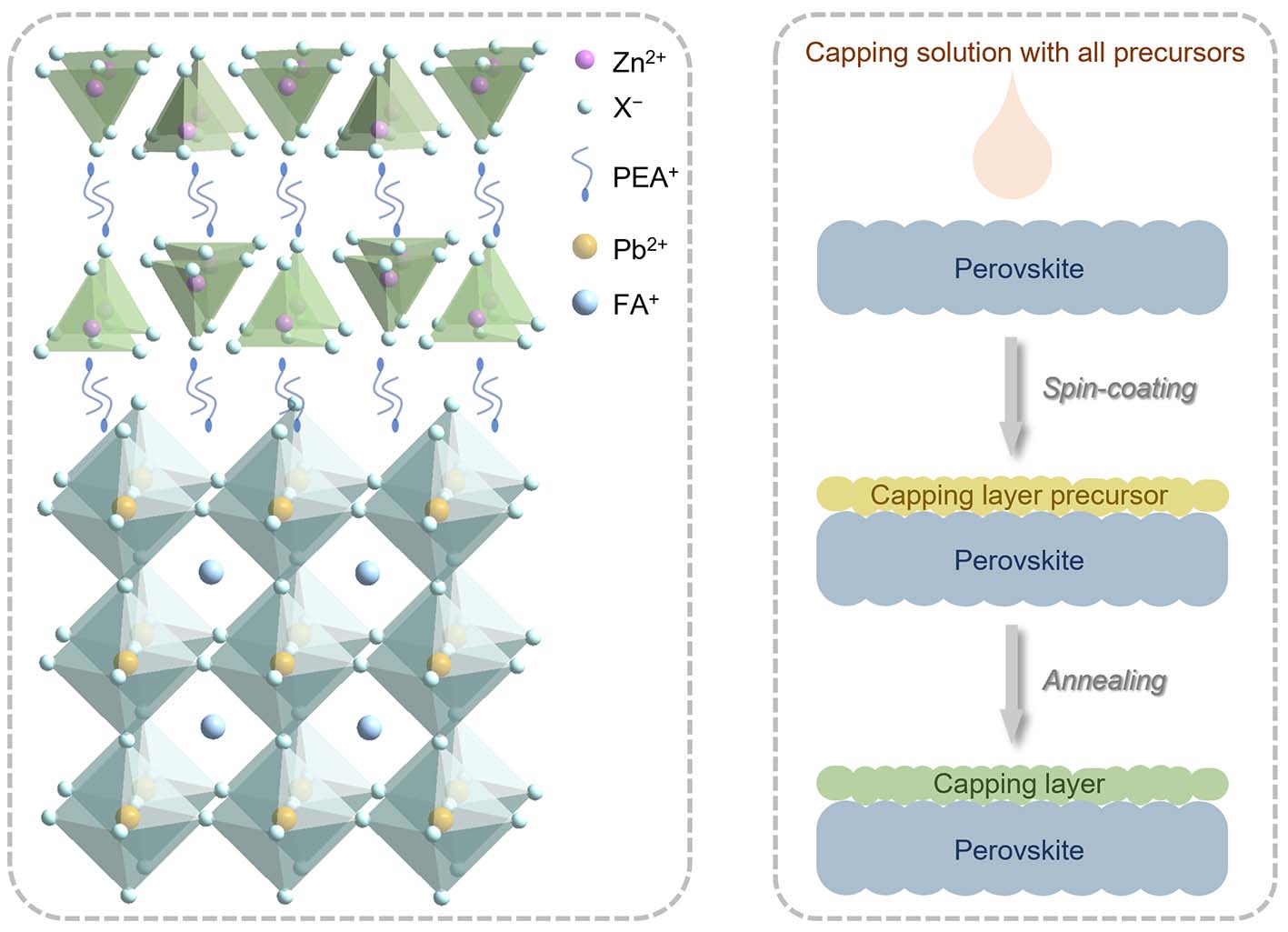

Perovskite photo voltaic cells are made from a number of layers of supplies, together with a perovskite layer that harvests mild and a capping layer. The capping layer is coated onto the perovskite layer to guard the photo voltaic cell from environmental stresses akin to warmth and moisture and to spice up the efficiency of the cell.

|

|

To make sure that the capping layer is appropriate with the underlying perovskite layer, researchers usually use an strategy known as the half precursor (HP) methodology to manufacture the capping layer. One of many precursor chemical compounds is first deposited on high of the perovskite layer which gives the opposite precursor. Via a course of referred to as cation trade response, the deposited precursor then reacts with lead ions current within the perovskite layer beneath to kind a lead-based chemical compound that makes up the capping layer.

|

|

On account of the HP methodology, lead can also be current within the protecting capping layer. A way that permits non-toxic metals for use within the capping layer could be a game-changer for perovskite photo voltaic cells.

|

|

To make perovskite photo voltaic cells extra environmentally pleasant, the NTU scientists devised an strategy, referred to as a full precursor (FP) answer methodology, to synthesise a capping layer that doesn’t comprise lead.

|

|

Utilizing the FP methodology, the scientists coated perovskites with options containing steel halide salts – compounds made from a steel and parts that embrace chlorine, fluorine and iodine – and phenethylammonium iodide (PEAI) that’s generally utilized to perovskites to enhance the efficiency of perovskite photo voltaic cells. PEAI comprises ammonium, a positively-charged ion that comprises nitrogen and hydrogen, which is significant for the chemical response.

|

|

| (Left) The molecular construction of perovskite (blue) with the zinc-based capping layer (inexperienced). (Proper) The complete precursor course of that the researchers used to coat the zinc-based capping layer onto the perovskite layer. (Picture: NTU Singapore)

|

Zinc-based compound leads the best way

|

|

The researchers discovered {that a} zinc-based compound PEA2ZnX4 synthesised utilizing the tactic was the simplest capping materials among the many different supplies examined.

|

|

Not like the HP methodology, there is no such thing as a want to attract lead ions up from the underlying perovskite layer to kind this protecting capping layer when the FP methodology is used. This paves the best way for the usage of non-toxic metals within the capping layer.

|

|

In line with the researchers, the FP course of can also be simpler than the HP methodology at fabricating the capping layer because the chemical compounds within the answer are in a position to react with one another straight on the floor of the perovskite.

|

|

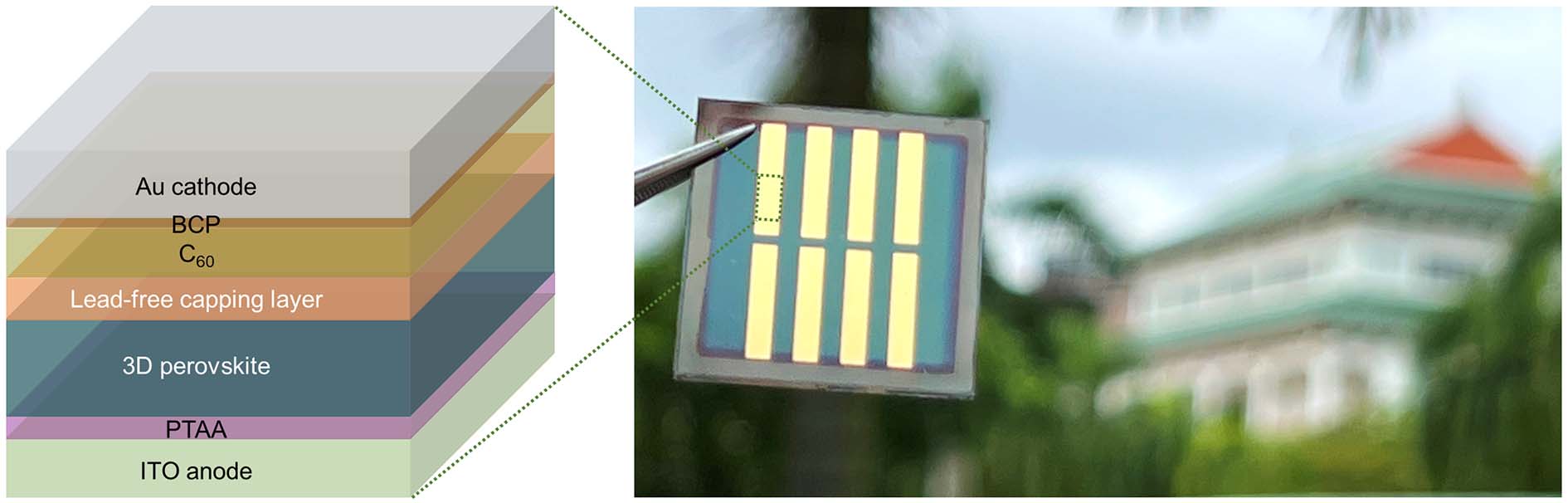

To manufacture a photo voltaic cell capped with PEA2ZnX4, the researchers first dissolved zinc halide salts and PEAI in a solvent known as acetonitrile, generally used for industrial functions. They then deposited the answer onto a rapidly-spinning perovskite layer hooked up to an electrically conductive glass substrate to kind a skinny and uniform layer – a course of referred to as spin-coating. The coated perovskite was heated at 100 levels Celsius for 10 minutes to bind the capping layer to the floor of the perovskite. The researchers then used a course of known as vacuum evaporation, through which a cloth is heated in a vacuum chamber to supply a vapour which is deposited on the coated perovskite, to synthesise the opposite layers of the perovskite photo voltaic cell.

|

|

Utilizing the FP methodology, the scientists created a 1 inch by 1 inch prototype photo voltaic cell capped with the zinc-based compound.

|

|

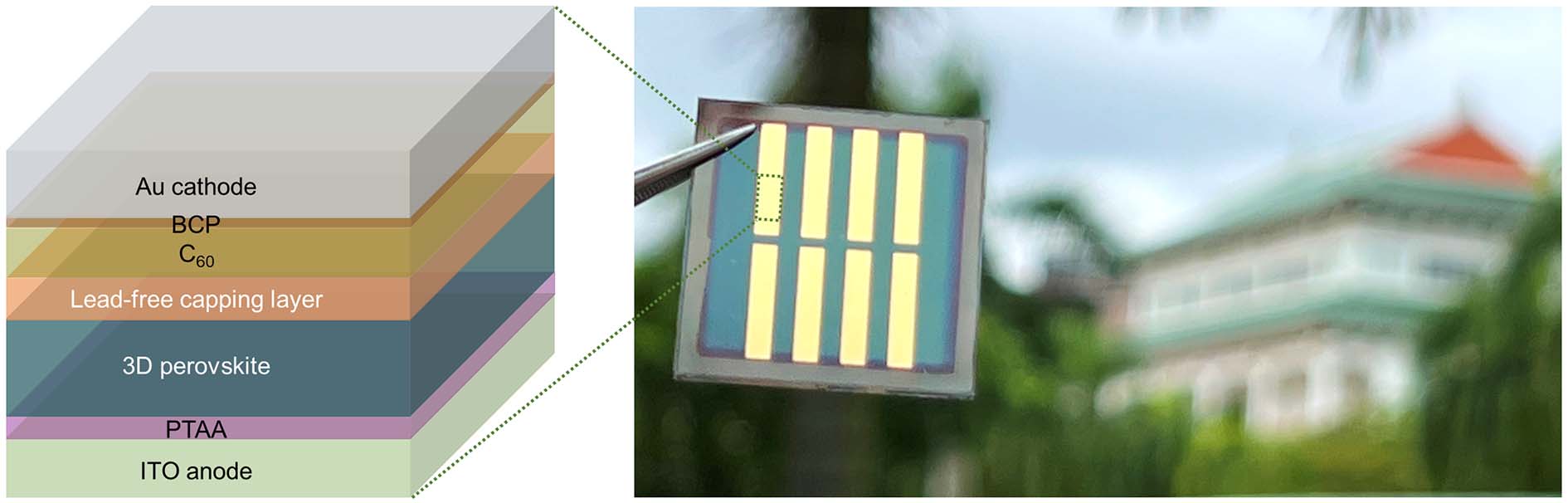

| (Left) A diagram exhibiting the totally different layers of the perovskite photo voltaic cell capped with the zinc-based capping materials fabricated by the researchers. (Proper) The dotted inexperienced rectangle signifies the energetic area of the perovskite photo voltaic cell that captures daylight and converts it to electrical energy. (Picture: NTU Singapore)

|

|

The scientists examined the zinc-based capping layer utilizing electron microscopy and spectroscopy and located that it didn’t have an effect on {the electrical} properties of the underlying perovskite layer. The capping layer additionally helped to cowl defects on the floor of the perovskite layer and improved its light-harvesting capabilities.

|

|

The researchers say that their methodology contributes to efforts to make perovskite photo voltaic cells extra environmentally pleasant. For instance, the tactic can be utilized along with lead-free perovskite supplies which can be presently being explored for the event of photo voltaic cells that may not launch poisonous metals when discarded.

|

|

The tactic additionally opens the potential for engineering the composition of the capping layer to boost the efficiency of perovskite photo voltaic cells.

|

|

“One of many greatest drawbacks of utilizing perovskite photo voltaic cells is their influence on the surroundings. By enabling zinc and different non-toxic metals for use within the capping layer, our innovation probably solves a serious impediment that stops the widespread use of perovskite photo voltaic cells,” stated Dr Ye Senyun, analysis fellow from NTU’s Faculty of Bodily and Mathematical Sciences, one of many lead researchers of the research.

|

|

Co-lead creator Dr Rao Haixia, analysis fellow from NTU’s Faculty of Supplies Science and Engineering, stated: “As our methodology doesn’t require extracting lead ions from the perovskite, this allows the potential for utilizing a variety of supplies to spice up the steadiness and effectivity of perovskite photo voltaic cells.”

|

|

The researchers discovered that the fabricated photo voltaic cell was as efficient at changing daylight to power as standard perovskite photo voltaic cells. In experiments with mild that simulated daylight, the photo voltaic cell might convert 24.1 per cent of the sunshine captured to electrical energy, near the very best effectivity achieved by perovskite photo voltaic cells to date. Compared, the very best licensed mild conversion effectivity of silicon photo voltaic cells is 25.2 per cent.

|

|

“The capping layer is an important element of a perovskite photo voltaic cell. This new strategy to style the capping layer is a serious milestone in designing perovskite photo voltaic cells with enhanced properties,” stated Professor Michael Grätzel, Director of the Laboratory of Photonics and Interfaces on the École Polytechnique Fédérale de Lausanne in Switzerland, who was not concerned within the research.

|

|

The prototype additionally demonstrated good reproducibility, with a mean mild conversion price of virtually 23 per cent over 103 cells examined. It had an extended lifespan, sustaining greater than 90 per cent of its potential to transform mild into electrical energy for greater than 1,000 hours of operation at full capability.

|

|

The efficiency of the system was additionally extra steady at excessive temperatures in comparison with units and not using a capping layer.

|

|

“By increasing the library of supplies that can be utilized, our findings unlock new alternatives for creating superior supplies for the capping layer, for extra environment friendly and steady perovskite photo voltaic cells,” stated Prof Sum. “This lead-free protecting capping methodology can be prolonged to different functions like perovskite mild emitting units, lasers and detectors.”

|

|

Prof Lam added, “As fossil fuels are depleting quickly, we have to harness renewable power assets akin to photo voltaic power significantly better. Eco-friendly and steady perovskite photo voltaic cells may very well be the reply and this innovation can probably propel a wider scale adoption of perovskite photo voltaic cells for photo voltaic power harvesting.”

|

|

The scientists are engaged on scaling up the tactic to manufacture full-sized photo voltaic cells. They’re additionally within the technique of submitting a patent with NTUitive, NTU Singapore’s innovation and enterprise firm.

|