| Feb 23, 2023 |

|

|

|

(Nanowerk Information) Nature has a unprecedented knack for producing composite supplies which might be concurrently gentle and powerful, porous and inflexible – like mollusk shells or bone. However producing such supplies in a lab or manufacturing facility – significantly utilizing environmentally pleasant supplies and processes – is extraordinarily difficult.

|

|

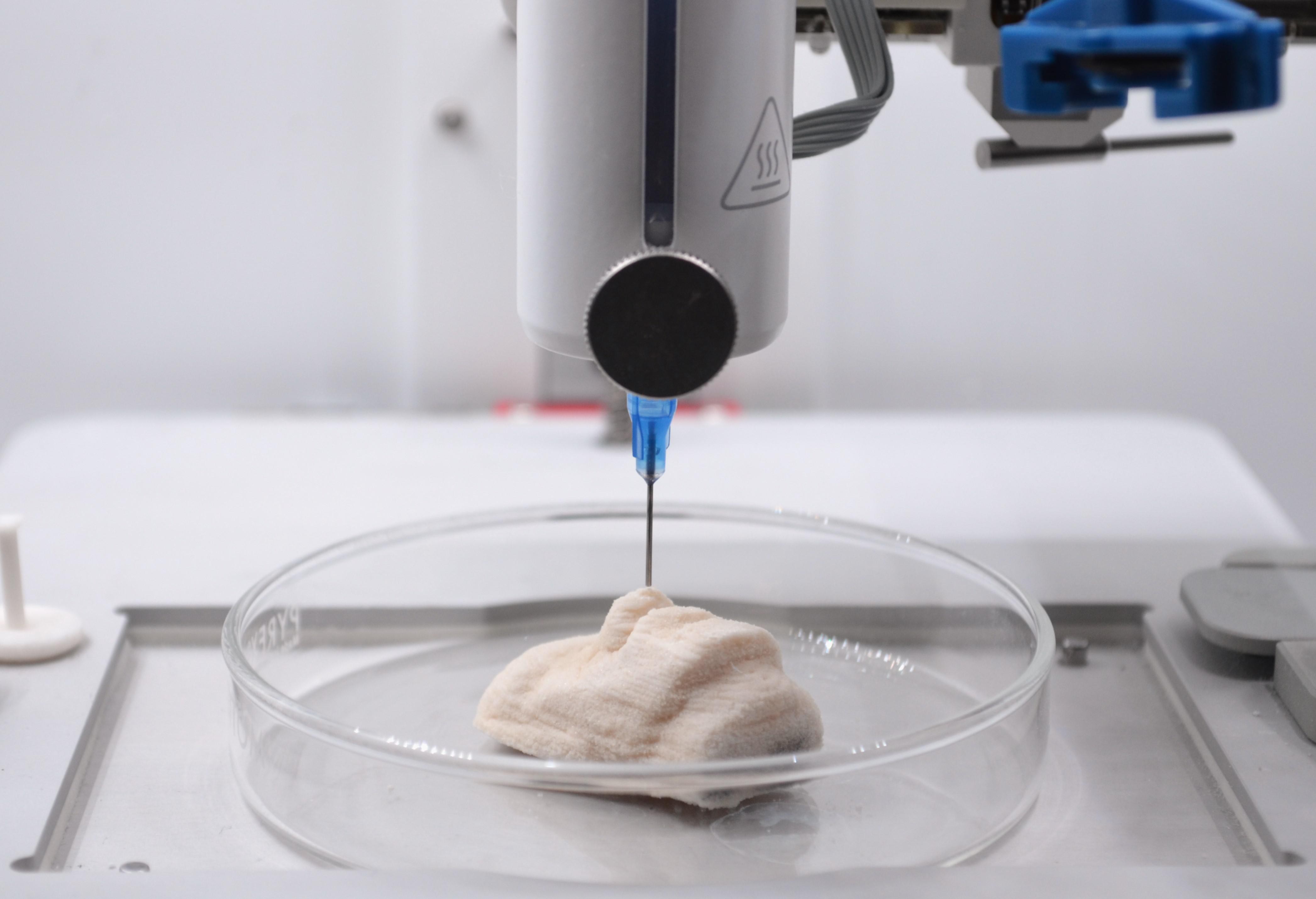

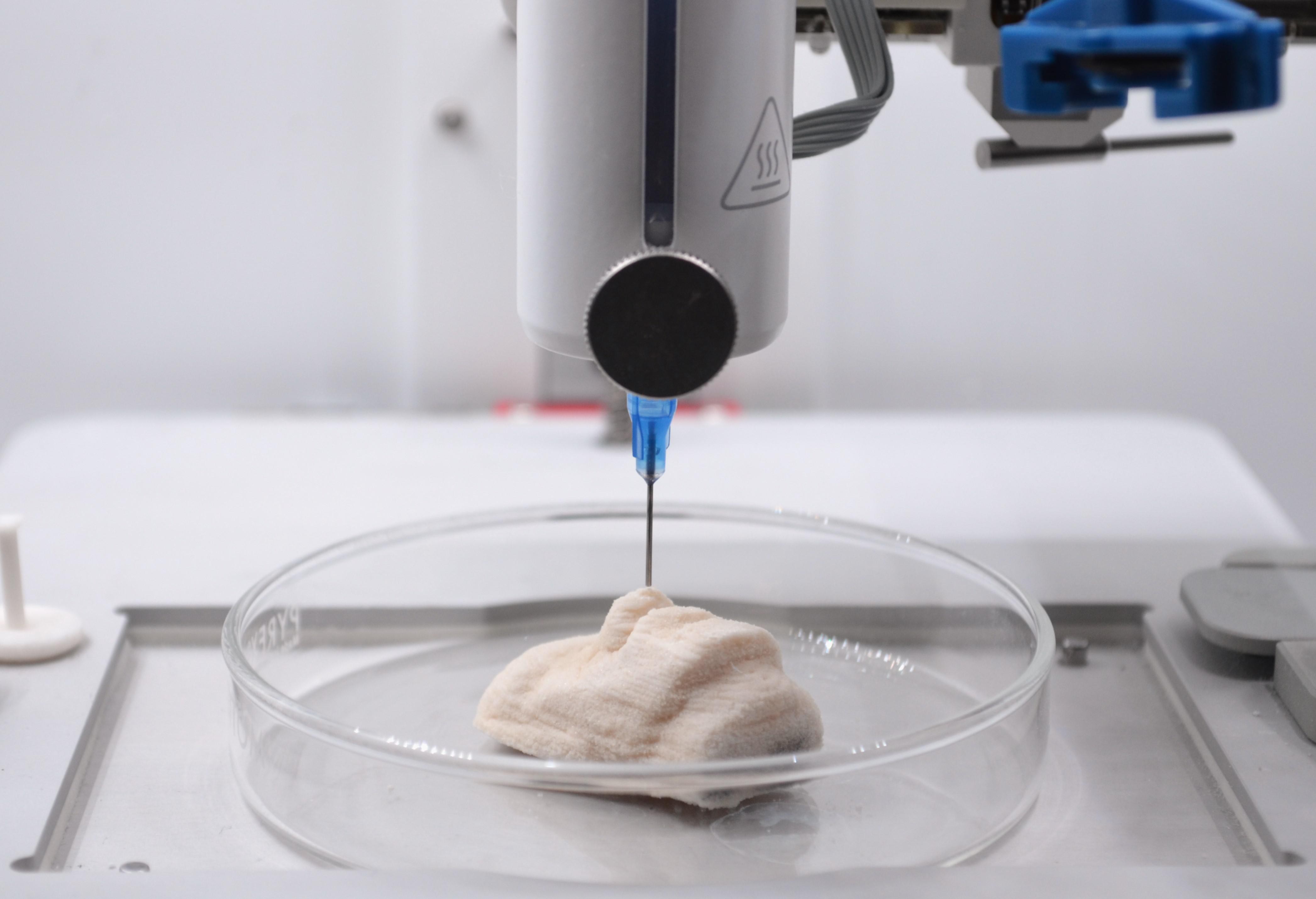

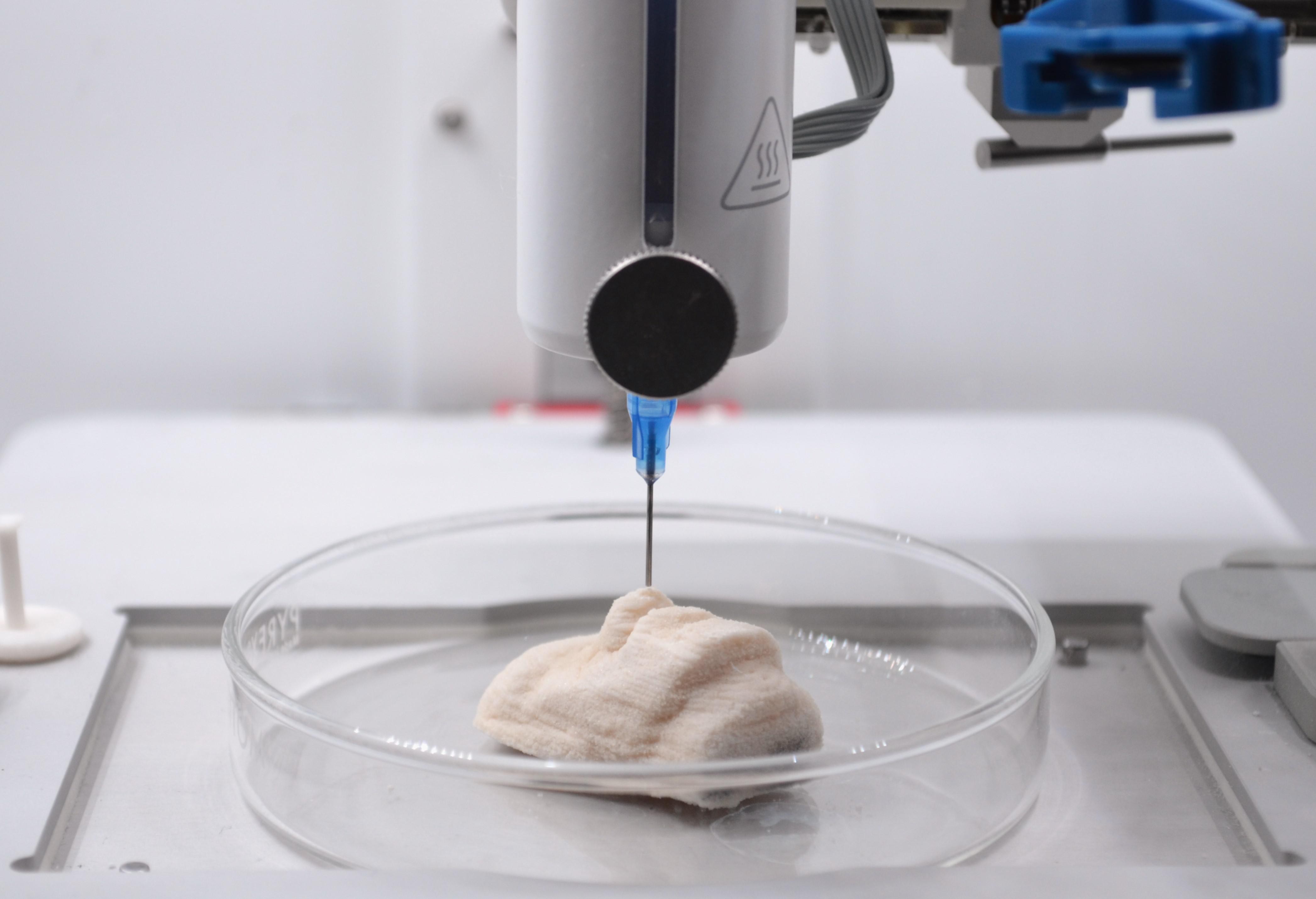

Researchers within the Comfortable Supplies Laboratory within the Faculty of Engineering turned to nature for an answer. They’ve pioneered a 3D printable ink that incorporates Sporosarcina pasteurii: a bacterium which, when uncovered to a urea-containing resolution, triggers a mineralization course of that produces calcium carbonate (CaCO3). The upshot is that the researchers can use their ink – dubbed BactoInk – to 3D-print just about any form, which is able to then regularly mineralize over the course of some days.

|

|

| A 3D-printed form utilizing BactoInk will mineralize inside just a few days. (Picture: Eva Baur)

|

|

“3D printing is gaining growing significance normally, however the variety of supplies that may be 3D printed is proscribed for the straightforward motive that inks should fulfil sure movement circumstances,” explains lab head Esther Amstad. “For instance, they need to behave like a strong when at relaxation, however nonetheless be extrudable by way of a 3D printing nozzle – kind of like ketchup.”

|

|

Amstad explains that 3D printing inks containing small mineral particles have beforehand been used to fulfill a few of these movement standards, however that the ensuing constructions are typically mushy, or to shrink upon drying, resulting in cracking and lack of management over the form of the ultimate product.

|

|

“So, we got here up with a easy trick: as a substitute of printing minerals, we printed a polymeric scaffold utilizing our BactoInk, which is then mineralized in a second, separate step. After about 4 days, the mineralization course of triggered by the micro organism within the scaffold results in a closing product with a mineral content material of over 90%.”

|

|

The result’s a robust and resilient bio-composite, which could be produced utilizing a normal 3D printer and pure supplies, and with out the acute temperatures typically required for manufacturing ceramics. Ultimate merchandise now not comprise dwelling micro organism, as they’re submerged in ethanol on the finish of the mineralization course of.

|

|

The strategy, which describes the primary 3D printing ink that makes use of micro organism to induce mineralization, has not too long ago been revealed within the journal Supplies Right now (“3D printing of dwelling structural biocomposites”).

|

|

| The strategy might be used to revive broken artworks. (Picture: Eva Baur)

|

Patching up artwork, coral reefs, or bone

|

|

The Comfortable Supplies Lab’s strategy has a number of potential purposes throughout a broad vary of fields, from artwork and ecology to biomedicine. Amstad believes that the restoration of artworks might be drastically facilitated by BactoInk, which can be straight injected right into a mildew or goal web site – a crack in a vase or a chip in a statue, for instance. The ink’s mechanical properties lend it the power and shrinkage resistance essential to restore a murals, in addition to forestall additional harm throughout the restoration course of.

|

|

The strategy’s use of solely environmentally pleasant supplies, and its capacity to provide a mineralized biocomposite additionally makes it a promising candidate for constructing synthetic corals, which can be utilized to assist regenerate broken marine reefs. Lastly, the truth that the biocomposite’s construction and mechanical properties mimic these of bone may doubtlessly make it fascinating for future biomedical purposes.

|

|

“The flexibility of the BactoInk processing, mixed with the low environmental impression and wonderful mechanical properties of the mineralized supplies, opens up many new potentialities for fabricating light-weight, load-bearing composites which might be extra akin to pure supplies than to right this moment’s artificial composites,” Amstad summarizes.

|

function myScripts() {

// Paste here your scripts that use cookies requiring consent. See examples below

// Google Analytics, you need to change 'UA-00000000-1' to your ID

(function(i,s,o,g,r,a,m)function(),i[r].l=1*new Date();a=s.createElement(o),

m=s.getElementsByTagName(o)[0];a.async=1;a.src=g;m.parentNode.insertBefore(a,m)

)(window,document,'script','//www.google-analytics.com/analytics.js','ga');

ga('create', 'UA-00000000-1', 'auto');

ga('send', 'pageview');

// Facebook Pixel Code, you need to change '000000000000000' to your PixelID

!function(f,b,e,v,n,t,s)

{if(f.fbq)return;n=f.fbq=function(){n.callMethod?

n.callMethod.apply(n,arguments):n.queue.push(arguments)};

if(!f._fbq)f._fbq=n;n.push=n;n.loaded=!0;n.version='2.0';

n.queue=[];t=b.createElement(e);t.async=!0;

t.src=v;s=b.getElementsByTagName(e)[0];

s.parentNode.insertBefore(t,s)}(window, document,'script',

'https://connect.facebook.net/en_US/fbevents.js');

fbq('init', '000000000000000');

fbq('track', 'PageView');

}